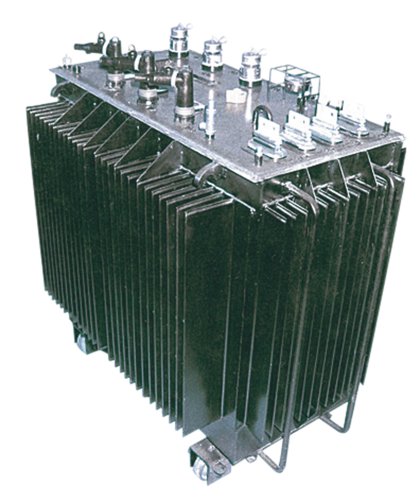

Transformadores Herméticos Sumergibles (de pozo)

Productos

Subestaciones

Prestigio y confiabilidad

Estos transformadores son aptos para instalación en cámaras subterráneas o fosas en las cuales existe el riesgo de inundación, estando previsto que los mismos puedan quedar sumergidos bajo agua. Son totalmente herméticos, en baño de aceite mineral, sin tanque de expansión, teniendo una cámara superior con nitrógeno seco para absorber la dilatación del aceite. El conexionado externo de Media Tensión se hace mediante conectores enchufables operables bajo carga, con pértiga. Toda la superficie exterior de la máquina lleva una protección superficial con pintura epoxibituminosa.

NORMAS

Se fabrican de acuerdo con las Normas IEC 76 y Complementarias.

APLICACIONES

Instalaciones inundables

NORMAS

Se fabrican de acuerdo con las Normas IEC 76 y Complementarias.

APLICACIONES

Instalaciones inundables