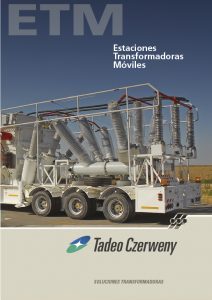

Estaciones Transformadoras Móviles

Estaciones

Transformadoras Móviles

Las Empresas de Transmisión y Distribución de Energía Eléctrica, se enfrentan cada día con el desafío de brindar un servicio seguro, confiable y con normas de calidad muy estrictas. Para evitar una disminución en la calidad de servicio, muchas de ellas han optado por duplicar la capacidad de transformación en cada estación transformadora. Esta solución representa en la actualidad costos financieros muy altos e inaceptables.

El negocio de la distribución de energía es de fuertes inversiones de capital. Por ello, éstas deben ser minimizadas sin descuidar la calidad de servicio. El stock de transformadores debe ser optimizado sin descuidar el crecimiento y las contingencias que puedan llevar a penalizaciones económicas de los Entes Reguladores y, peor aún, de los mismos clientes.

En este contexto, Tadeo Czerweny S.A. se ha puesto a la vanguardia de los proveedores de las Empresas de Transmisión y Distribución de Energía Eléctrica, proponiendo proyectos concretos para la minimización de los costos de capital: las Estaciones Transformadoras Móviles.

La incorporación de Estaciones Transformadoras Móviles en la Dirección Técnica de una Empresa de Energía, estratégicamente distribuidas en el área de abastecimiento de energía, reduce considerablemente los costos de capital y de mantenimiento de la calidad de servicio. El tiempo requerido para su efectiva puesta en servicio, una vez transportada al lugar de operación con velocidad de 50km/h por caminos pavimentados, es de tres a cuatro horas.

Estaciones Transformadoras Móviles (ETM) construidas:

Ventajas adicionales de las ETM'S :

Responder a demandas estacionales de carga a bajo costo.

Disminuir los costos de mantenimiento en las Estaciones Transforma doras tradicionales.

El suministro de energía temporario, permite reducir los cortes de energía por mantenimiento a cero, con la ventaja adicional de reali zar sin tensión todas las tareas de mantenimiento sobre el transfor mador y equipos asociados.

Rápida provisión de energía para casos extraordinarios, como catás trofes o inundaciones.

Provisión de energía, en tiempo y forma, para grandes obradores.