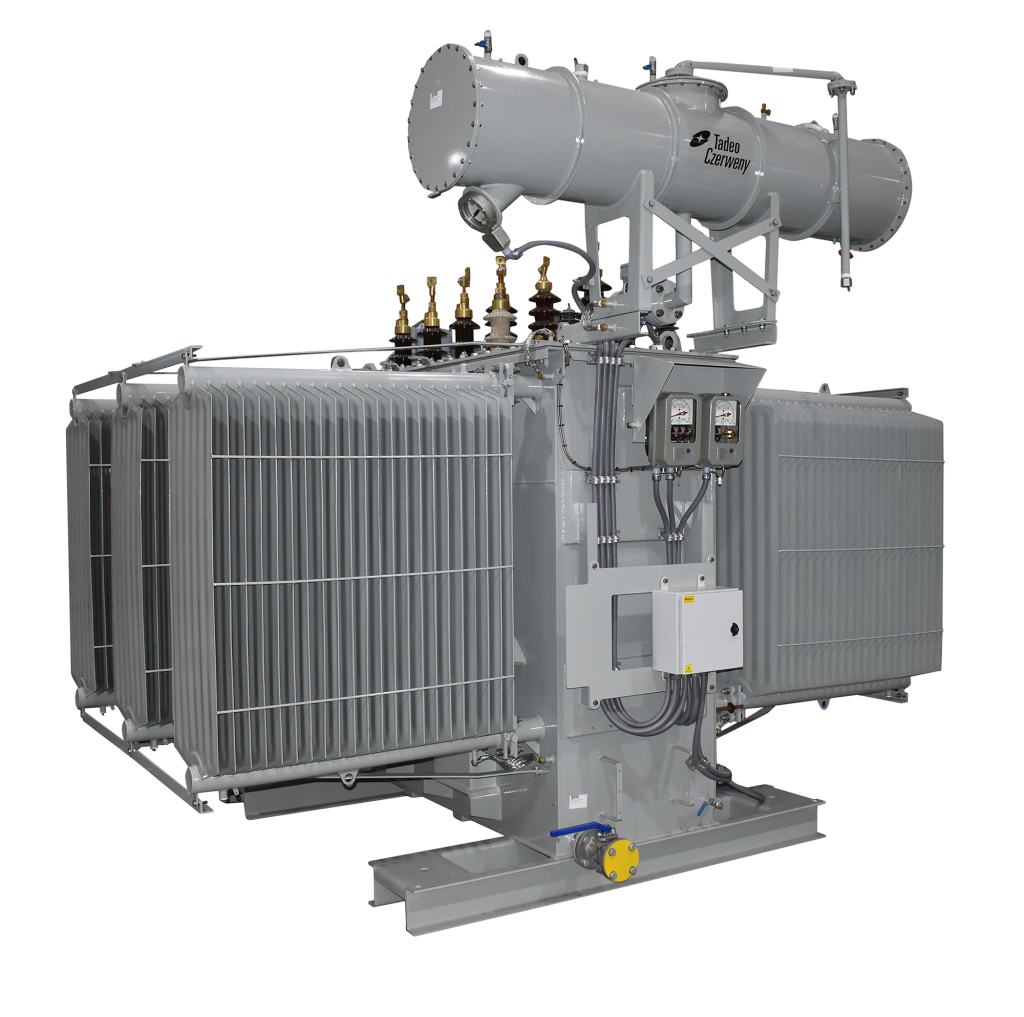

Transformadores de Distribución

Transformadores

de Distribución

Prestigio y Confiabilidad

Referentes en el mercado y avalados por nuestra amplia experiencia de más de sesenta años de fabricación, nuestros transformadores se caracterizan por tener el menor índice de fallas en servicio.

Nuestra línea de transformadores de Distribución está diseñada para su instalación sobre piso o sobre plataformas aéreas (dependiendo de la potencia) en líneas de distribución de energía urbanas y suburbanas, con tensiones de hasta 35 kV.

Su fabricación responde a las Normas IRAM 2269, IRAM 2250, IRAM 2476, IEC 60076 ó ANSI C57; o con diseños especiales adaptados a las necesidades de la industria.

Se construyen con o sin tanque de expansión. En este último caso, los de tipo hermético, pueden ser llenado integral o con cámara de aire/nitrógeno.

Todos los transformadores se proveen con un conmutador sin tensión accionable externamente, en un todo de acuerdo a las Normas en vigencia. A pedido pueden proveerse con otros rangos de conmutación.

Generalidades constructivas

APLICACIONES

- Distribución de energía

- Industrias en general

- Oil & Gas

- Minería

- Siderurgia

- Elevadores para generación solar, eólicos y otras renovables.

- Emprendimientos residenciales y comerciales