Transformadores de Llenado Integral (sin Cámara de Nitrógeno)

Prestigio y confiabilidad

Para satisfacer las necesidades de un mercado cada vez más exigente, Tadeo Czerweny S.A. viene desarrollando y perfeccionando desde hace años el modelo de “Transformadores de Llenado Integral”. Ampliamente aceptado y de uso casi exclusivo en Europa, este producto ha sido optimizado hasta tener aplicaciones en tensiones de hasta 36 kV.

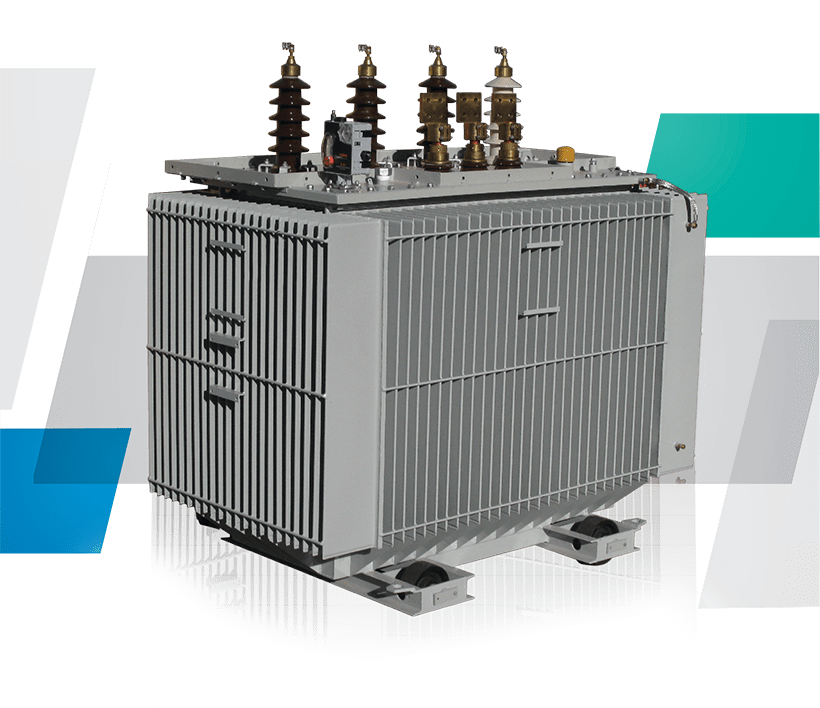

CARACTERÍSTICAS TÉCNICAS

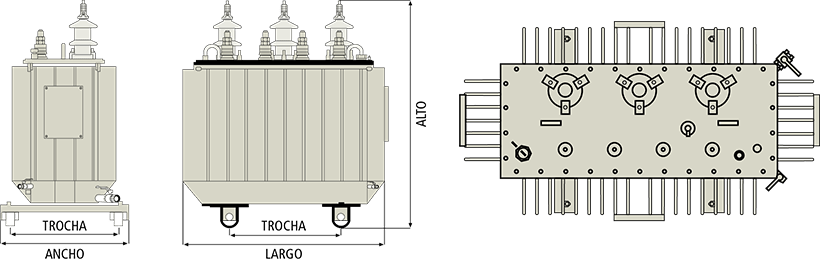

Estos transformadores cumplen con las prescripciones de las Normas IRAM en lo que respecta a potencia, tensiones, nivel de aislamiento, régimen de sobrecargas, etcétera. A pedido también se pueden producir bajo especificaciones particulares de cada cliente u otras normas internacionales. Para facilitar su intercambiabilidad con otro tipo de máquinas mantienen las trochas y ruedas establecidas por IRAM 2250. Al ser un transformador hermético (sin tanque de expansión) su estructura trabaja a presión variable en función de la temperatura del aceite, sin intercambio de aire con el exterior. Esto permite que el aceite del transformador nunca esté en contacto con el medio ambiente, lo que impide el ingreso de humedad preservando los inhibidores de oxidación y por ende prolongando la vida útil del transformador. La principal diferencia con las máquinas herméticas tradicionales es que no cuenta con una cámara superior de Nitrógeno, ya que por diseño estas máquinas compensan las fluctuaciones de volumen de aceite mediante la expansión y contracción de sus paredes aletadas. Por diseño la presión en el interior de la cuba, a la máxima temperatura del aceite, nunca sobrepasa los 4,9 N/cm2.

El núcleo está construido con chapa de acero silicio de grano orientado de bajas pérdidas específicas, con espesores comprendidos entre 0,23 y 0,35 mm. Son del tipo tres columnas de núcleo apilado o núcleo arrollado, corte STEP LAP especialmente diseñado para reducir a valores mínimos la corriente de vacío.

PROVISIÓN ESTÁNDAR

- Tres aisladores de alta/media tensión de porcelana.

- Cuatro aisladores de baja tensión en porcelana.

- Un conmutador de cinco posiciones de accionamiento sin tensión.

- Una válvula para extracción de muestra de aceite.

- Una válvula para desagote del aceite.

- Una tapa de llenado.

- Una placa característica.

- Cáncamos de izaje, transporte y decubado.

- Una terminal de puesta a tierra.

- Cuatro ruedas bi-direccionales.

- Explosores de dos etapas en alta/media tensión.

-

- Conectores tipo banderas para alta/media y baja tensión.

- Termómetro de aceite (con o sin contactos).

- Descargadores de Oxido de cinc.

- Aisladores enchufables (c/s carga) tipo Loadbreak/DEADBREAK bushings.

- Válvula de sobrepresión (c/s contactos).

- Brida para cubrebornes según especificaciones.

- Cubrebornes para Alta/Media y Baja Tensión.

- Instrumento de Protección Integral*

Planos

*Este último accesorio altamente recomendado principalmente para potencias iguales o superiores a 400 kVA, tiene la particularidad de combinar en un solo instrumento mediciones de: Temperatura, Presión, Nivel e Indicación de Acumulación de Gases, cumpliendo en este último caso una misión similar a la de un Relé Buchholz. Estos aparatos de protección y medición, vienen equipados con selectores de temperatura para emitir señales de alarma y disparo. Las otras tres mediciones sólo emiten una señal de disparo cada una.