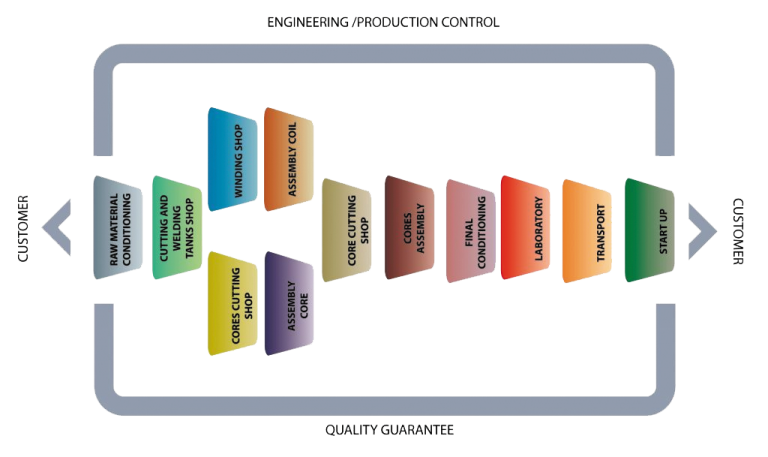

Productive Processes

Our “know how” is the result of a rigorous methodology, many years of experienced work transmitted to every member of our staff. And a productive system that integrates the engineering, the quality and the computing as solid support.

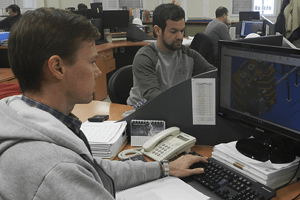

Engineering

All the positions in the workplace are connected to a net and NT Server typical of engineering, functioning as the system administrator of all the information in this section.

Besides they are communicated, by a modern fiber optic link, to a second Server that commands, through the Programming Area, SIM (Integrated Manufacturing System).

It is worth noticing that, although computers have been used as fundamental tools for the designs during many years, we have made a great leap forward in using Parameterized Software in the Mechanical Desktop platform. This important development has enabled us, from the basic electric calculation of a transformer classified by regulations, to get the plans for manufacturing in a short time and without mistakes.

Highly trained designers

Highly trained designers

Fully Computarized working positions

Continuously updated software

Manufacturing Integrated System {S.I.M}

R & D Department

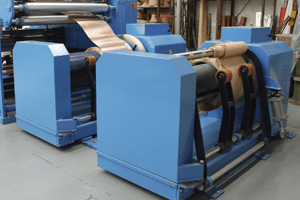

Foil Winding process

Foil Winding process

Maximum width 1200 mm. Distribution coils

Distribution winding section

Distribution winding section

High Voltage coils

Power winding section

Power winding section

Vertical winding machine

Core cutting section

Core cutting section

Step-lap automatic cutter

Pole-mounted assembly section

Pole-mounted assembly section

Kanban manufacturing system

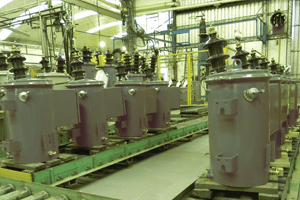

Distribution assembly section

Distribution assembly section

Kanban manufacturing System

High Voltage Laboratory section

High Voltage Laboratory section

Impulse generator